Terry,

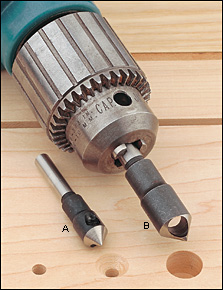

Get this ONE in a 3/8" size. It was recommended to me by a local luthier/repair guy. I have tested it, and it is totally chatter free with a hand drill!

Tracy

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Chatter free countersink http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=8475 |

Page 1 of 1 |

| Author: | Terry Stowell [ Sat Sep 16, 2006 2:38 am ] |

| Post subject: | |

Recommendations for a chatter free countersink? I'm buying blade stiffeners from Lee Valley and want to buy something else.. I've had poor results with some contersinks. What works well and at what speed, for irregular grain, esp for BRIDGES? I've seen ball mills, unibit step drills, single and multi flute countersinks. I need smooth! But do I have to clamp every time I countersink? |

|

| Author: | Steve Saville [ Sat Sep 16, 2006 3:11 am ] |

| Post subject: | |

Terry, What are the dimensions of your holes, both pilot and countersinnk? They make comination drills. |

|

| Author: | Billy T [ Sat Sep 16, 2006 6:01 am ] |

| Post subject: | |

I have found the single lip countersinks work the best. The multifaced cutting provides too much cutting surface which overcomes the rigidity of the drill press and chuck. The single-lip also tends to burnish the chamfer to some degree. In wood, I generally use a relatively high speed and light feed. This seems to prevent tearout, relatively well. Billy Dean |

|

| Author: | LuthierSupplier [ Sat Sep 16, 2006 6:13 am ] |

| Post subject: | |

Terry, Get this ONE in a 3/8" size. It was recommended to me by a local luthier/repair guy. I have tested it, and it is totally chatter free with a hand drill!

Tracy |

|

| Author: | Mark Tripp [ Sat Sep 16, 2006 8:04 am ] |

| Post subject: | |

Yup! What Tracy said. They work GREAT! -Mark |

|

| Author: | Terry Stowell [ Sat Sep 16, 2006 1:09 pm ] |

| Post subject: | |

Thanks. Just what I thought, just by the nature of the design, I thought it would work. |

|

| Author: | CarltonM [ Sat Sep 16, 2006 1:11 pm ] |

| Post subject: | |

Yeah, those zero-flute sinks work really well. However, don't waste your time with the cheap imports. They'll just disappoint you by not being sharpened appropriately to begin with, and by dulling too quickly. Don't panic, though. Even the good ones in the sizes we use shouldn't cost more than ten bucks. |

|

| Author: | Terry Stowell [ Sat Sep 16, 2006 1:34 pm ] |

| Post subject: | |

Yeah, I think I had one of the cheapies that dissappointed. I'm ordering some blade stiffeners from Lee Valley, and I'll get a couple other goodies too! Thanks guys! |

|

| Author: | Lillian F-W [ Sat Sep 16, 2006 2:26 pm ] |

| Post subject: | |

Thanks Tracy. I have been trying to remember where I saw them. |

|

| Author: | Mario [ Sat Sep 16, 2006 3:24 pm ] |

| Post subject: | |

For bridges, I use a cone-shaped stone in a Dremel. No chance of tearout, and produces a lovely countersink. And the aroma of BRW smoke... ah.... I use the same cone(this Dremel is set aside with this stone in it all the time, I use it so much) for also esing the edges of the tuner holes, for the bushings, for the end pin, and for the bolt holes in the body. Anything that needs a slight chamfer.... |

|

| Author: | Jim Watts [ Sat Sep 16, 2006 3:48 pm ] |

| Post subject: | |

Mario, How do keep the stone from loading up? |

|

| Author: | Jim Watts [ Sat Sep 16, 2006 3:52 pm ] |

| Post subject: | |

Shane, I use coarse, medium and fine. Typically buy my my fret fret wire from LMI or Allied as I like it coiled. Will you be selling it staight or coiled? |

|

| Author: | Mario [ Sun Sep 17, 2006 3:03 am ] |

| Post subject: | |

How do keep the stone from loading up? It doesn't load up. At least, not enough to affect it. |

|

| Author: | CarltonM [ Sun Sep 17, 2006 12:35 pm ] |

| Post subject: | |

[QUOTE=ToddStock] Woodcraft used to carry Weldon[/QUOTE] Reid Tool carries Weldon. www.reidtool.com Look under "cutting tools" for countersinks. |

|

| Author: | Todd Rose [ Mon Sep 18, 2006 1:41 am ] |

| Post subject: | |

[QUOTE=Mario] For bridges, I use a cone-shaped stone in a Dremel. No chance of tearout, and produces a lovely countersink. And the aroma of BRW smoke... ah.... I use the same cone(this Dremel is set aside with this stone in it all the time, I use it so much) for also esing the edges of the tuner holes, for the bushings, for the end pin, and for the bolt holes in the body. Anything that needs a slight chamfer....[/QUOTE] Thanks for the tip, Mario. Great idea. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|